paint impact test procedure|best paint impact tester : broker Coordination: Work together in a harmonious reciprocal manner. Requirements must be stated clearly so that they can not be misunderstood. Measurements are then taken continually to .

webProfile Views: 316,991. Videos Watched: 23. Kellyta Tharsys's Videos. Play All Videos. Most Recent. 2:53. MOSTREI TUDO na viagem em Porto Galinhas. 16.4K views. 76% .

{plog:ftitle_list}

WEBTwinCon Enterprises Ltd. 503 likes · 21 talking about this. Excavation and Earthworks company that excels in subdivision development, civil work, drilling and blasting, road .

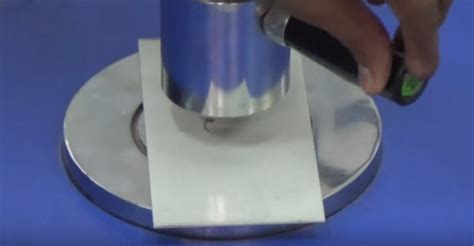

ASTM D 2794 provides a procedure for rapidly deforming by impact a coating film and its substrate and for evaluating the effect of such a deformation. The organic coatings under test are applied to four or more suitable thin metal panels.There are two kinds of test that are performed to determine the impact resistance of paints: Weight falls on a punch which is set on the coated metal sheet also known as Indirect Paint Impact Test. Weight attached to a punch falls on a .This test involves applying organic coatings to suitable 24 gauges metal panels and dropping a standard weight from a certain distance to induce an indenter deforming the coating as well as the substrate. Micom Laboratories offers .

Test Procedure and Acceptance Criteria for — Prime Painted Steel Surfaces for Steel Doors and Frames 1 Scope These methods prescribe the procedures to be followed in the selection . Discover impact testing methods like Charpy, Izod, and drop weight & learn how they ensure material safety, toughness, and reliability across industries.Coordination: Work together in a harmonious reciprocal manner. Requirements must be stated clearly so that they can not be misunderstood. Measurements are then taken continually to . The Impact Tester is a widely used device for the coating and plastic industries. In both industries impact resistance is measured by a falling weight from a.

ASTM D2794 Impact Resistance Of Paint and Coatings This test method covers a procedure for rapidly deforming by impact a coating film and its substrate and for evaluating the effect of .ISO 1520:2006 specifies an empirical test procedure for assessing the resistance of a coating of paint, varnish, or related product to cracking and/or detachment from a metal substrate when subjected to gradual deformation by indentation . An impact test is used to determine a material’s impact strength, or the material’s ability to resist deformation when subjected to a sudden shock or impulse load. . ASTM A370, and ASTM D256 govern the exact testing .Impact tester for paint. Impact test of paint coatings applied to metal base. ISO, DIN, ASTM. The Impact Tester is used for measuring the resistance of coatings to impact. Thanks to it you can simulate the production of cracks and peeling, resistance to shocks, the flexibility, adherence and elongation of coatings.

In the paint and coating industries, paint adhesion testing is often used to determine if the paint or coating will adhere properly to the substrates to which they are applied. Several tests measure the resistance of paints and coatings from substrates: cross-cut test, scrape adhesion, pull-off test, and others. [1]ASTM D2794 is a standard test method for resistance of organic coatings to the effects of rapid deformation (impact). This test involves applying organic coatings to suitable 24 gauges metal panels and dropping a standard weight from a certain distance to induce an indenter deforming the coating as well as the substrate.

Test Procedure and Acceptance Criteria for — . 3.3 Impact test The paint shall be tested per ASTM D2794-93 (2010)e1 Standard Test Method for Resistance of Organic Coatings to the Effects of Rapid Deformation (Impact), with 20 inch pounds of direct impact using a Gardner Impact Tester with .IMPACT TEST SP1880, SP1890, SP1891, SP1895 1 SAFETY PRECAUTIONS The Impact Test has been designed to be as safe as possible. However as with all . applies before using your impact tester. The following procedure is only a guideline to ensure safe use during testing. Please always follow the complete protocol as given in the used standard.Package & Product Drop Testing. Drop testing is a procedure used to evaluate how a package and its contents react to impacts such as free-falls, tumbles, and other types of handling during the shipping and distribution environment. . ASTM D5277 – The use of an Incline Impact test machine can be used to help diagnose damage which may result .

ASTM B117 Salt Spray Test Procedure: The duration for conducting the ASTM B117 salt spray test can vary depending on the requirements and industry standards. Common test durations include 24, 48, 72, or even up to 1,000 hours. The chosen test duration typically reflects the expected or desired durability of the materials and coatings being .Test Methods Standards • Film thickness ISO 2808; B.S. 3900D5 • Gloss ISO 2813; ASTM D523; DIN 67530 • Flow (orange-peel) • Color: Visual ISO 3668 • Colorimetry ISO 7724 • Adhesion (cross-cut test) ISO 2409; ASTM D3002 • Impact resistance ISO 6272; ASTM D2794 • Cylindrical mandrel ISO 1519; ASTM D1737; bend test DIN 53152; NFT 30040 Rapid deformation test (impact resistance) of coatings according to ISO 6272-1

Paint testing reveals that about 75% of paint durability failures are related to adhesion problems. The remaining failure cases are related to discoloration or visual change such as cracking and crazing. . Paint drying times are specified under ASTM test procedure D1640. These tests provide contractors and builders a guideline for the .

STRC is here for your paint and coating testing service. Book your testing with sigma laboratory. . Hardness Test: This test method covers a procedure for rapid, inexpensive determination of the film hardness of an organic coating on a substrate in terms of pencil leads of known hardness. . Impact Resistance Test: Impact performance after .The salt spray test (or salt fog test) is a standardized and popular corrosion test method, used to check corrosion resistance of materials and surface coatings.Usually, the materials to be tested are metallic (although stone, ceramics, and polymers may also be tested) and finished with a surface coating which is intended to provide a degree of corrosion protection to the underlying .

for Testing Paint, Varnish, Conversion Coatings, and Related Coating Products D823 Practices for Producing Films of Uniform Thickness . Procedure 7.1 Select an area free of blemishes and minor surface imperfections. For tests in the field, ensure that the surface is clean and dry. Extremes in temperature or relative humidity

cation defoaming procedures. In this article, three fundamentally different issues are addressed with regard to the testing and development of new defoamers for low-VOC archi-tectural formulations. First, the critical variables in both the shaker and dissolver test methods are identified. It is only after these variables are foundrescent UV-Condensation Exposures of Paint and Related Coatings.” ASTM D2794-93(2004), “Standard Test Method for Resistance of Organic Coatings to the Ef-fects of Rapid Deformation (Impact).” ASTM D3359-02, “Standard Test Method for Measuring Adhesion by the Tape Test.” ASTM D4060-01, “Standard Test Method for Test panel painting procedure consists of the followings: - 1 - Selection of test panel. 2 - Surface Preparation. 3 - Coating & Painting. 4 - Inspection / Testing

iphone 8 plus drop test case

The “peel test” is a typical industry standard procedure that offers the opportunity to see under real conditions that the tape has been applied correctly. According to the manufacturer, the adhesion should be cohesive (see photo 1) and should adhere to both the substrate and the pipe itself.Testing Conditions:Paint testing is carried out both on liquid paints and on cured coatings. Depending on the application, these are subjected to varying loads – under laboratory conditions or in outdoor weathering. For this purpose, the researchers use standardized test procedures, but also develop customized test and testing methods if required.Izod Impact Test Understanding the Izod Impact Test: A Comprehensive Guide Introduction In the realm of materials testing, the Izod Impact Test stands out as a critical method for assessing the impact strength of plastics and other polymers. This test, integral to the offerings at Kiyo R&D Center & Laboratory, is a dynamic means to [.]

One of the most common tests, at least in the United States, of the physical characteristics of plastic materials is the notched izod impact test as specified by ASTM D256 Standard Test Method for Determining the Izod Pendulum Impact Resistance of Plastics.. How the Izod Impact Test Works 作为重要的表面涂层, 该涂层旨在保护基材免受外部环境和机械损伤. 在实际应用中, 薄膜必须能够承受各种机械冲击而不破裂或脱落. 这种能力称为抗冲击能力, which is one of the key properties of the film [.]1. This Standard provides guidance and procedures for Fragment Impact testing. Testing should be conducted by participating nations as a part of the Insensitive Munition (IM) assessment of munitions where required by STANAG 4439, Policy for Introduction, Assessment and Testing for Insensitive Munitions. 2. This Standard specifies 2 test .Test Procedures for Pigmented Organic Coatings on Extruded Aluminum;" and . (1.2 mil) total film thickness. Paint process capability may result in readings below 25 microns (1.0 mil). No more than 5% of the total readings, . 7.5 IMPACT RESISTANCE . 7) 5 .

Test Procedure: The specimen is placed horizontally in the testing machine, with the notch facing the direction of the impact. A pendulum hammer is released from a known height, striking the specimen at a predetermined velocity. . The test, primarily used for coatings, assesses the impact resistance of paint, varnish, or other coatings. A . This allows the coating to perform well. The primary methods used to test paint adhesion are explained below. 1. Cross-cut test by tape test method ASTM D3359 — Standard test methods for rating adhesion by tape test This test method covers procedures to assess the adhesion of coating films to metallic substrates. This is done by applying and .For both types, the procedures for evaluating characteristics such as color, gloss, impact, adhesion, weathering and corrosion resistance are the same as for cured liquid coatings. The testing of powder coatings differs from their liquid counterparts in the characterization of the powder itself. This includes tests such as: Melt flow

paint impact test

paint impact resistance test

webPulseira Pandora, Charms, Joias de Ouro, Joias de Diamantes, Anéis, Brincos e Colares. Descubra peças exclusivas em 10x sem juros, com entrega rápida e segura!

paint impact test procedure|best paint impact tester